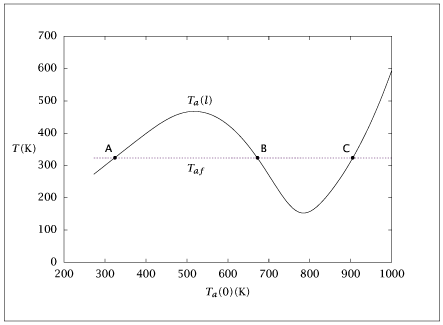

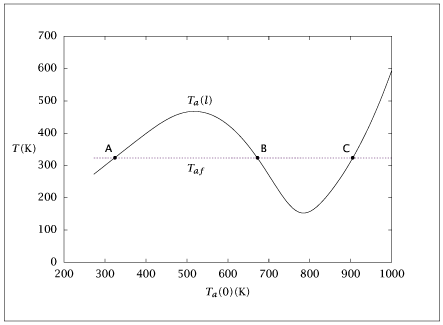

Figure 6.38:

Coolant temperature at reactor outlet versus temperature at reactor inlet; three steady-state solutions.

Code for Figure 6.38

Text of the GNU GPL.

main.m

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101 | % Copyright (C) 2001, James B. Rawlings and John G. Ekerdt

%

% This program is free software; you can redistribute it and/or

% modify it under the terms of the GNU General Public License as

% published by the Free Software Foundation; either version 2, or (at

% your option) any later version.

%

% This program is distributed in the hope that it will be useful, but

% WITHOUT ANY WARRANTY; without even the implied warranty of

% MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU

% General Public License for more details.

%

% You should have received a copy of the GNU General Public License

% along with this program; see the file COPYING. If not, write to

% the Free Software Foundation, 59 Temple Place - Suite 330, Boston,

% MA 02111-1307, USA.

% This program simulates the tubular reactor model for ammonia

% synthesis

%

% Revised 8/14/2018

p.P = 300; % atm - pressure of the reactor

p.R = 82.05e-6; %(m^3 atm)/(mol K) - Gas constant

% p.v0 = 0.16; % m/sec

% Repairing bug.

% Change velocity to get profile C in Figures 6.40, 6.41

% jbr, 3/5/07

p.v0 = 0.05713; % m/sec

p.A = 1; % m^2 - Cross sectional area available for reaction

%p.UA = 1/3; % 1/m

p.UA = 1/2; % 1/m

p.delG0 = -4250; % cal/mol ammonia

p.delH0 = -12000; % cal/mol ammonia

p.Tstd = 298; % K

p.Rg = 1.987; % cal/mol K

p.K0 = exp(-p.delG0/(p.Rg*p.Tstd)); % equilibrium constant at Tstd=298

%p.deltaH = 495; % K/mol

p.deltaH = - 2.342 ; % s K/mol

p.tau = 1500; % K

p.Ta0 = 323; % K - entering coolant (feed) temperature of the reacting gas

p.len = linspace(0,12,100)'; % m - length of reactor

%

% UA corresponds to Ua/C where U is the heat transfer coefficient, a is

% the total heat exchanging surface per unit length of the converter

% and C is the feed rate expressed as heat capacity per unit time.

%

% deltaH is the temperature rise of the reacting gas corresponding to

% the adiabatic formation of 1 mole of Ammonia.

%

% The following set of constants correspond to the rate constants(k1m

% and k2m) and activations energies/gas constants(E1m,E2m) of the

% forward and reverse reactions. Tm is the

% mean temperature which has been used to reparameterise.

%

p.k0 = 7.794e11; % reverse rate constant

p.E = 20000; % K reverse rate activation energy

%

% Initial flows

%

initial.Q0 = p.v0*p.A; % m^3/s

initial.Nt0 = initial.Q0*p.P/(p.R*p.Ta0);

xn0 = 0.985*0.25; % N_2 feed mole fraction

xh0 = 0.985*0.75; % H_2 feed mole fraction

xnh0 = 0.015; % Ammonia feed mole fraction

%

% Plot a graph showing multiple intersections of coolant feed

% temeperature Ta0 and solution to ODE on coolant side T(:,3)

%

nTs = 100;

Tvec= linspace(273,1000,nTs)';

Taend = zeros(nTs,1);

Trend = zeros(nTs,1);

xnhvec = zeros(nTs,1);

for i = 1:nTs

T = Tvec(i);

inital.Nnh0 = xnh0*initial.Nt0;

inital.Nh0 = xh0*initial.Nt0;

inital.Nn0 = xn0*initial.Nt0;

x0 = [inital.Nnh0; T; T];

opts = odeset('AbsTol', sqrt(eps), 'RelTol', sqrt(eps));

[tsolver, x] = ode15s(@(t, x) ivpjbr(t, x, p, inital), p.len, x0, opts);

NT = inital.Nn0 + inital.Nh0 + 2*inital.Nnh0 - x(:,1);

Taend(i) = x((length(x)),3);

Trend(i) = x((length(x)),2);

xnhvec(i) = x((length(x)),1)./ NT(length(x));

end

table = [Tvec p.Ta0*ones(nTs,1) Taend Trend xnhvec];

save -ascii ammonia_shooting.dat table;

if (~ strcmp (getenv ('OMIT_PLOTS'), 'true')) % PLOTTING

plot (table(:,1),table(:,2:3));

% TITLE

end % PLOTTING

|

ivpjbr.m

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25 | function xdot = ivpjbr(t, x, p, initial)

Nnh = x(1);

T = x(2);

Ta = x(3);

RT = p.R*T;

Nn = initial.Nn0 - 1/2*(Nnh - initial.Nnh0);

Nh = initial.Nh0 - 3/2*(Nnh - initial.Nnh0);

Nt = Nn + Nh + Nnh;

pn = (Nn/Nt)*p.P;

ph = (Nh/Nt)*p.P;

pnh = (Nnh/Nt)*p.P;

qadd = (Ta - T)*p.UA;

k = p.k0*exp(-p.E/T);

K = p.K0*exp(-p.delH0/p.Rg*(1/T - 1/p.Tstd));

rxrate = k/RT* (K^2 * pn*ph^(1.5)/pnh - pnh/ph^(1.5));

xdot = zeros(3, 1);

xdot(1) = p.A * 2*rxrate;

% Van Heerden fudge factor; for comparison purposes only

% xnh = Nnh/Nt;

% taufix = - 2*tau*A*(1+xnh)/Nt;

% xdot(2) = qadd - rxrate*taufix;

xdot(2) = qadd - rxrate*p.deltaH;

xdot(3) = qadd;

|